To ensure that the impact of the P2O process on the environment was minimal, Plastic2Oil committed significant resources to air emissions stack testing with CRA, a global environmental consulting company.

Airborne Emission Test Results

Since the Company’s inception, the Plastic2Oil process has undergone several stack emissions tests under the supervision of the New York State Department of Environmental Conservation (NYSDEC), performed by Conestoga-Rovers & Associates (CRA).

The P2O process emissions are well within the accepted parameters for air emissions for the State of New York.

Historically, the Plastic2Oil process has been issued its required permitting in a timely fashion in New York State, traditionally one of the stricter states in the US to seek permitting.

In December 2011, CRA completed the stack tests analyzing the emissions from the P2O process.

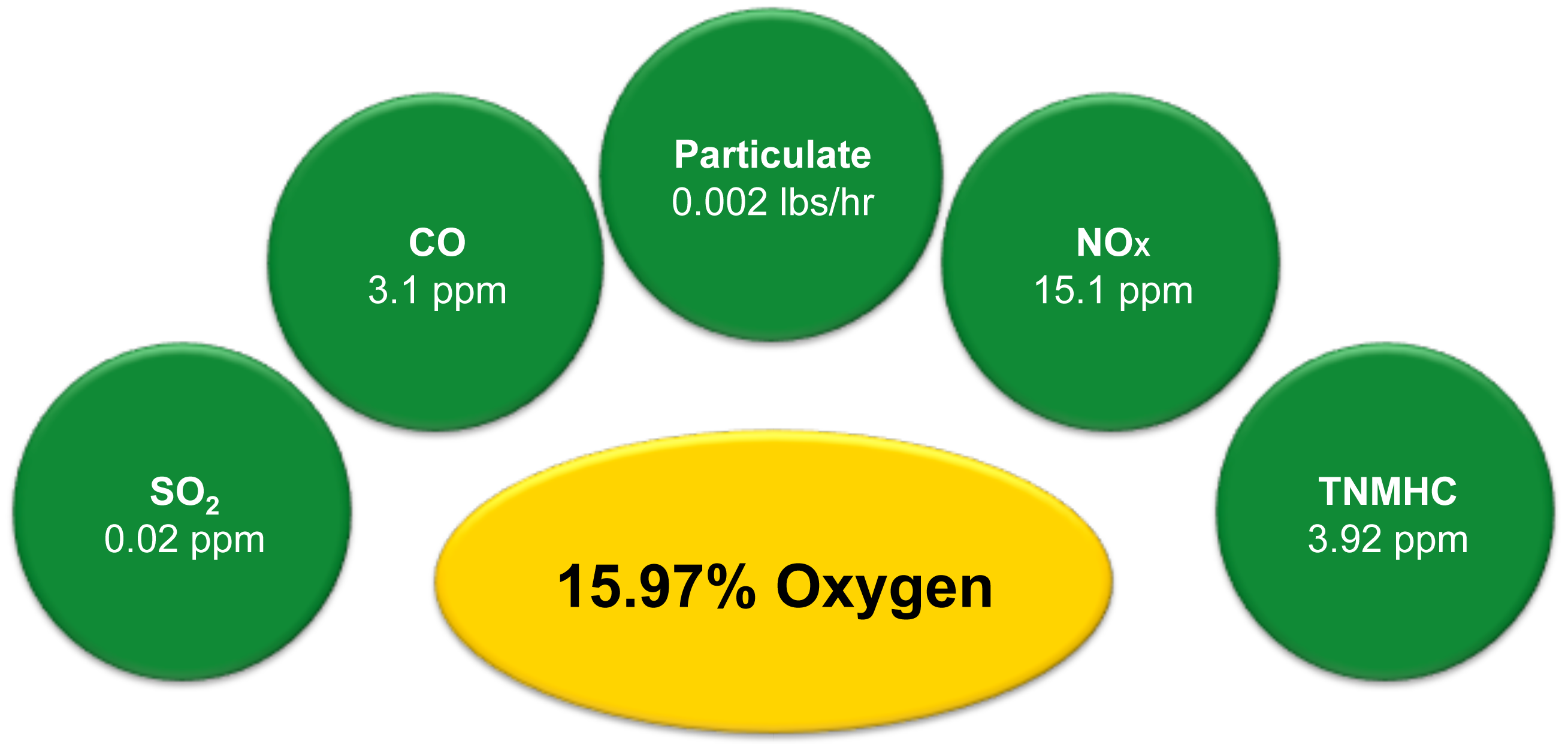

The profile of the emissions generated by the process during the second test is shown below.

The CRA results from the stack tests completed in both September 2010 and December 2011 reaffirm other findings that the operation of the P2O processor is a clean, "green" process.

The stack test from December 2011 was performed on the existing commercial processor with a pre-melt system and produced results showing emissions decreased with increased plastic feed rates; further validating that the P2O process is highly green, clean and scalable.

The emissions documented by CRA from the P2O stack test were lower than what would be produced by the same test on a natural gas furnace of similar size.

The process puts a high percentage of oxygen back into the air, with minimal harmful emissions, well within the regulatory criteria established by the NYSDEC.

The company underwent a stack test in December of 2012 in conjunction with seeking permitting to run heat transfer fluids (HTF), which act as plastic densifiers and heat exchange agents, with plastic feedstock.

The results of the December 2012 stack test further validated the process and confirmed that the P2O process emits approximately the same emissions of a natural gas furnace of the same size.

Other Material Residue

An average of 86% of the process output is usable fuel and another approx. 10-12% of the process output is off-gases. The final approx. 2-4% is a plasticized carbon black residue, which is below TCLP standards for safe landfill disposal. Subsequent testing also indicates this residue has a heating value of 10,600 BTU/lb, making it appropriate for use by heavy industry, such as steel manufacturers for the purposes of fuelling blast furnaces.